In the world of pool construction and maintenance, a gamechanging product has emerged, promising to redefine the durability and longevity of pool surfaces. MicroGlass, a penetrating liquid that reinforces the weakest elements pool finishes with a chemically resistant compound, is making significant strides in the pool industry.

Let’s take a closer look at the transformative impact of MicroGlass, its scientific underpinnings, application processes, industry adoption, and the versatile solutions it offers to both new and existing pools.

MicroGlass is a spray-applied hardener that is poised to reshape the way the industry views interior pool finish preservation. Compatible with all types of cementitious finishes such as marcite, quartz plaster, pebble, and other aggregate finishes, it addresses the inherent challenges faced by pool surfaces over time. The key lies in its ability to deeply penetrate the full depth of the finish, where it then reacts with the softest and most soluble parts of the finish (calcium hydroxide). After entering the microvoids, it instantly converts the weakest parts of the finish into a glass-like compound. This transformation results in an internal microstructure that is not only substantially harder but also more chemically resistant, providing a robust solution to issues like etching, pigment loss, craze cracking, hydration stains and other common plaster headaches.

MicroGlass, developed over two decades ago by a concrete scientist in Florida, is founded on a scientific approach that permanently alters the internal composition of the interior finish. MicroGlass causes a one-time chemical reaction inside the microstructure of the surface. This reaction permanently infuses the finish with a glass-like silicate that that essentially freezes the plaster in time. And because acid, salts, chlorine, and water itself has a difficult time breaking down the glass-like byproduct created by MicroGlass, the outcome is a ceramiclike material with significantly increased hardness. By addressing the solubility of calcium hydroxide in water, MicroGlass ensures that the plaster remains resistant to the normal chemical changes that occur when submerged in water. And unlike sealers or coatings that sit on the surface, this transformation takes place within the matrix. Meaning the finish will look and feel like a normal interior finish, but with bolstered chemical defense.

Alan Smith, now MicroGlass Chairman and former CEO of Alan Smith Pools utilized the protective product with his successful remodel company in Orange, California. Alan emphasizes that until the industry can effectively tackle the challenges posed by calcium hydroxide, a key component comprising 24% to 26% of the Portland cement matrix, plaster longevity will remain a persistent concern. MicroGlass stands out by not merely covering the existing issues on the surface but by fundamentally changing the internal matrix, offering a proactive solution to cement degradation.

One of MicroGlass’s notable advantages is its user-friendly application process. Applicators armed with a battery powered sprayer and a paint roller can seamlessly apply the product to pool surfaces prior to filling. The simplicity of the process allows for easy adoption by service technicians, making it a practical protective offering to prolong the life of a customer’s finish following a cleaning service. While MicroGlass is simple to install, preparing the existing pool finish (acid washing, neutralizing the surface with sodium bicarbonate solution, sanding/buffing rough areas, repairing cracks or spalling) does require a skilled expertise that is best done by a pool professional.

The cost- effectiveness of MicroGlass, sold in 5 gallon buckets, further contributes to its appeal. With materials cost at a couple of hundred dollars for most pools, coupled with an application fee, MicroGlass proves to be an economically viable investment for both service providers and their pool owners. The potential return on investment is substantial, given the boosted extension of a pool’s usable lifetime and the reduction of long-term maintenance costs and plaster-related warranty claims. And thanks to the increased resistance to harsh pool chemicals, a MicroGlass treated finish can withstand more acid-washes than an unprotected pool, meaning future scale and surface stains are easier to mitigate with chemical treatment.

MicroGlass demonstrates its versatility by catering to both new and existing pools. For brand-new pools, it serves as a game-changer by minimizing the labor-intensive startup work associated with new plaster. The product virtually eliminates the common issue of plaster dust, streamlining the initial phases of pool ownership. Because MicroGlass protects vulnerable cement as the finish water-cures, the treatment also reduces the visibility of craze cracks and hydration staining from that dreaded pop-up shower during fill. Some service techs offer a MicroGlass application to their builders prior to filling the pool since the protection reduces the fluctuating calcium levels that traditionally spike as the water leeches calcium—all leading to a more efficient startup with less chemicals.

For new quartz and pebble finishes, its applied after the final acid-wash and surface neutralization. For nonexposed finishes, MicroGlass is applied after final-set (meaning once you can walk on the finish and not leave indentations). However, caution is advised when using MicroGlass on brand-new smooth troweled plaster (marcite) finishes if calcium chloride is used in the mix. The calcium chloride, when not water-wand washed or acidwashed like on exposed finishes,

MicroGlass applied to new exposed aggregate finish and allowed to permeate(left). Animation of matrix penetration (top right). Results under a microscope: MicroGlass converted soft calcium into a glass-like silicate(bottom right). Image Credit: MicroGlass.

Untreated(left) and MicroGlass treated(right) pebble samples placed in undiluted muriatic acid. Note color in untreated(left) bath due to cement etching vs. right bath. See pg.15 for results after 2 minutes. Image Credit: MicroGlass.

will produce a whitening effect on the new non-exposed finish.

Existing pools, on the other hand, benefit from MicroGlass by reducing chemical damage, etching and pigment-loss. The protection also makes future scale and stains easier to clean with chemical treatments which traditionally would further etch or degrade an unprotected finish. This transformative solution not only preserves the aesthetics of the pool but also enhances its resilience to the effects of continuous use and environmental factors. Keep in mind, if a surface is soft, flaking, spalling or soft, there may not be enough calcium hydroxide in the finish for MicroGlass to convert. In these situations, the company recommends a full replaster followed by a protection to protect the new finish.

MicroGlass is rapidly gaining traction as an essential addition to the pool industry toolkit. Its simplicity of application, coupled with its profound impact on pool surface durability, positions it as a valuable asset for pool professionals seeking innovative solutions.

MicroGlass is not merely a product; it is a transformative force within the pool industry— with it’s staff of poolpros now offering advisory on best practices for acid-washes, innovative methods for acid neutralization, stain mitigation and advice on polishing/ buffing existing finishes. MicroGlass continues to gain traction among the largest plaster applicators and commercial service companies in the nation. MicroGlass offers a range of virtual training resources, install guides, and offers phone support to discuss projects and application. The product is available for purchase at Heritage owned distribution companies nationwide. For those wanting in-person training contact MicroGlass to learn about both free and paid hands-on events.

As it continues to gain momentum, it stands as a testament to innovation and a catalyst for reshaping industry standards. By addressing the core challenges associated with pool surface degradation, MicroGlass offers a sustainable solution that ensures not only the longevity of pool surfaces but also the satisfaction of pool owners.

In pool construction and maintenance, MicroGlass has emerged as a beacon of progress, providing a solid investment that promises years of enjoyment in the backyard oasis.

For more information, visit www. microglassllc.com.

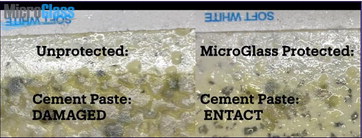

Untreated (left) and MicroGlass protected (right) shown side by side after 2 minutes in undiluted muriatic acid. Note the loss of cement paste in the untreated sample (left) vs the MicroGlass protected sample (right). This is an accelerated damage model that displays how MicroGlass reduces chemical damage and calcium extraction. MicroGlass’ protection from soft calcium hydroxide deterioration means increased acid wash frequency and more manageable calcium levels for the pool pro and pool owner. Image Credit: MicroGlass.

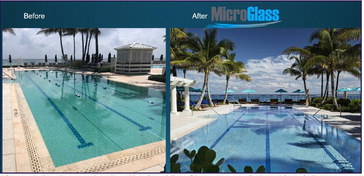

After a drain, clean and stain mitigation, MicroGlass was applied to this existing exposed aggregate finish to extend the service life of this 5-star commercial pool in West Palm Beach, FL. Image Credit: MicroGlass.